Get in touch with us for any questions or quotes on surveying services and products. We will respond back as soon as we can.

FDI Creative Services, Inc.

Mooring Line Inspection

Zupt’s 3D Recon is used for contactless mooring line inspection as a more efficient alternative to the industry convention of “go, no-go” calipers for wear and simple ROV video footage. Easily manipulated by either a Work Class or Inception Class ROV, 3D Recon quickly models the mooring line or chain links to a pixel resolution of less than a millimeter to provide highly accurate models to measure chain-link wear without physically contacting the mooring line. Zupt’s deliverable provides data to be stored and compared with future surveys to automatically detect wear rates of the mooring line.

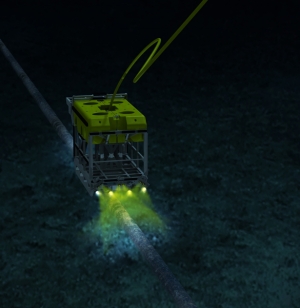

Precise Relative-Positioning

Zupt’s 3D Recon technology provides a real-time relative-to-structure positioning solution for external ROV-mounted sensors. Zupt’s 3D Recon provides a relative, sub-centimeter position to any external sensors that are also interfaced with the subsea vehicle. Necessary for many integrity management surveys, such as contactless cathodic protection, 3D Recon not only eliminates the need for a complicated ROV positioning solution for relative positioning but also provides a sparse and dense point cloud for the external vehicle sensors to overlay their data.

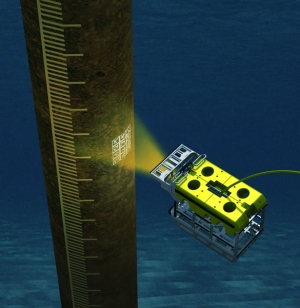

Structure Modeling

Developed specifically for integrity management surveys of subsea structures, 3D Recon generates high-resolution 3D models of any structure surveyed. This 3D deliverable provides the detail necessary to analyze corrosion, measure anode depletion, inspect anomalies, and more. 3D Recon integrates 3 machine vision cameras with an inertial navigation system in a compact 4000-meter rated subsea housing. The offshore team interfaces 3D Recon to the ROV as a standalone sensor (no external positioning solution necessary) to efficiently collect data to generate a highly accurate 3D model. 3D Recon solution provides a real-time quality control interface to provide the offshore user a simple program to determine there are no voids in the data collected.

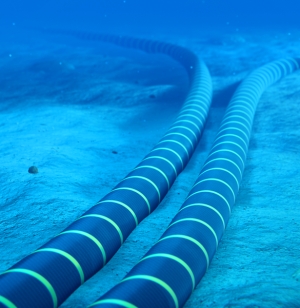

Pipeline Inspection

Zupt’s pipeline inspection-specific technology integrates an inertial navigation system with 5 high-definition cameras to accurately model a greater area of visible pipeline and nearby seabed. In a single, efficient pass of the pipeline, the ROV or AUV flying the pipeline will collect the necessary data to generate a high-resolution point cloud or mesh model of the pipeline section along with any potential free span. The pipeline deliverable provides details on any corrosion, anomalies, length and depth of free span, anode depletion, and more. The resultant pipeline model is scalable and can be integrated with the vehicle positioning solution to provide the absolute position of the entire pipeline survey.

3D Recon V2

3D Recon V2 is a subsea stereo imaging system that produces high-resolution, geospatially accurate 3D models of what is seen subsea. Housed in a compact subsea enclosure rated for depths up to 4,000 meters, it features two high-resolution machine vision cameras and a high-performance MEMS IMU. By integrating inertial technology with imaging sensors, 3D Recon V2 can generate real-time sparse point clouds for navigation and quality control, as well as high-density 3D models that help engineers make informed decisions about the integrity of their subsea assets.

3D Recon V2 Applications

While 3D Recon V2 was initially developed for Integrity Management (IM) and Inspection, Repair, and Maintenance (IRM) purposes. Its versatility has since led to adoption in a range of other applications, including::

- Jumper/Spool Metrology

- Mooring Chain Link Inspection

- Hull Inspection

- Pipeline Out-Of-Straightness (OSS) Surveys

- Pre-Install/As-Built Documentation

- Real-Time Relative-to-Structure Positioning

- Real-Time Object Detection and Pose Estimation of Underwater Objects.

How 3D Recon V2 Works

3D Recon V2 leverages the ‘3D reconstruction’ methodology, advanced computer vision, and inertial navigation techniques to generate camera poses, point clouds, object detection, and pose estimation of underwater objects. It supports both real-time and highly optimized offline dense point cloud generation. Here's how each pipeline works:

Real-Time Dense Point Cloud:

- Alignment: IMU data determines the sensor's orientation (heading, pitch, roll).

- Feature Detection: Cameras capture images at 5-10Hz, and features are identified based on intensity variations.

- Feature Matching: Descriptor vectors are computed for features and used for matching between stereo cameras and sequentially from frame to frame, creating a sparse point cloud (approximately 5-10cm pixel resolution).

- Navigation Integration: The navigation engine integrates acceleration and angular velocity data to update navigation states (position, velocity, attitude).

- Global Matching: Matching features with existing ones in the map occurs.

- Position Projection: Features are projected from the camera frame to the global frame.

- Consistency Checks: Checks ensure alignment with the global map, utilizing RANSAC and optimization.

- Navigation Update: Successful feature matches update the state and covariance; new features are added to the map.

- Path Optimization: Data collection for map optimization involving keyframes triggered by specific events.

- Dense Point Cloud Generation: High-density point clouds are generated using computed position and orientation and utilize disparity maps created by comparing light intensity between the left and right cameras.

- SLAM: Camera pose, trajectory estimation, and dense point cloud generation occur in real time, allowing the operator to see their position relative to the structure, track their path, and assess coverage. When previously mapped areas are revisited, a loop closure event is triggered, correcting accumulated drift in camera pose and trajectory to ensure globally consistent dense point clouds.

Offline Dense Point Cloud:

- Feature Detection: Similar to the real-time dense pipeline, this pipeline also detects features from every image captured by the cameras but extracts higher-quality features than the real-time dense pipeline.

- Feature Matching: Descriptor vectors are computed for features and used to match every image collected. Unlike the real-time dense pipeline, this pipeline also performs non-sequential image matching.

- Structure from Motion: Structure from Motion and Bundle Adjustment algorithms are utilized to optimally estimate the 3D positions of features and the camera poses for each captured image. This process creates a sparse 3D point cloud along with the estimated camera poses at the time each image was taken.

- Dense Point Cloud Generation: High-density point clouds are generated using computed camera poses and disparity maps created by comparing light intensity between patches around sparse features across all images.

- Mesh Generation: Once the dense point cloud is generated, surface normals are computed for each point using its three nearest neighbors, which define a local plane. This process results in a highly detailed 3D model of the structure.

Real-Time Detection and Pose Estimation of Underwater Objects:

- Deep Learning model training: State of the art Deep Learning models are trained using collected and annotated data to recognize a certain object. The model learns to detect the object and generate bounding boxes and confidence scores of its predictions.

- Keypoint prediction: The model and pipeline also generate specific ‘Key Points’ used for pose estimation.

- Pose Estimation: Using known correspondences between the 2D Key Points and the corresponding object’s dimensions, the pose of the object relative to the cameras are calculated using the Perspective-n-Points algorithm.

3D Recon V2 Key Features

- Linear, Angular, and Area Accuracy: Because of the tightly coupled inertial navigation solution, 3D Recon V2 offers accurate spatial scaling within the dense delivered models. This precision ensures reliable data for measurement-based assessments.

- Change Detection: One of the key advantages of 3D Recon V2 is its ability to automate change detection. Automated Change Detection is a powerful feature that becomes accessible through the utilization of models generated by 3D Recon V2. By comparing historical 3D models, operators can monitor structural changes over time for proactive IM decisions.

- Additional Sensor Integration: 3D Recon V2 can integrate data from other sensors (Contactless CP, hydrocarbon sniffers, etc.), providing a comprehensive model or heat map for structural integrity analysis.

Deliverables of 3D Recon V2

3D Recon V2 delivers high-resolution, geospatially accurate 3D models with submillimeter pixel resolution. These precise models support the subsea integrity community in making informed decisions about structural health over time. 3D Recon V2 integrates seamlessly into existing workflows, providing high-resolution still images, conventional video, and 3D models generated both in real time for verification and offline for detailed inspection.

Data Acquisition Requirements

We require a survey mux to integrate the 3D Recon V2 spread. All power, serial communications, and image data are connected to the Mux/ROV through a single PBOF cable. It relies on one RS232 and one GB Ethernet port for configuration and data transmission. Power requirements are 24Vdc at 150W.

Product Specs

- Type of Application – Marine

- Year of Introduction – 2020

- Length - 77.9 cm

- Width - 59.4 cm

- Depth - 30.0 cm

- Weight in Air - 34Kg

- Weight in Water - 23Kg

- Power Requirement - 24VDC 6A / 150W

- Serial Communications - RS232 (230400 bps)

- Housing – Titanium

- Rated - 4,000 m

- Sensor Type - Active Pixel CMOS, Global Shutter Resolution - 2028 x 2448

- FoV Horizontal - 85°

- FoV Vertical - 65°

- Number of Frames Per Second - 5 - 10 fps Copper & 10 - 20 fps SM Fiber

- Start Up Time - 0.02 s

- Communication - 1 Gbps Ethernet Copper & 10 Gps

- SM Fiber - Single Fiber Channel

- Software – Included

- Export Image Formats - Color palletized Mesh, Point Cloud *.ply (Binary)

- Battery Type - No Battery

Contact Zupt today to learn more about 3D Recon and how it can enhance your subsea operations.

VertiCAM

VertiCAM is one of two real-time, contactless inclination monitoring sensors offered by Zupt. VertiCAM determines the verticality (pitch and roll) of a tubular structure during installation (pile, monopile, conductor, wind turbine foundation [WTF], pile, etc.). VertiCAM is an in-air system, not a subsea system.

VertiCAM includes two LiDAR systems, two cameras, and inertial measurement units. The structure is detected in real-time by the LiDAR camera systems from two different points onboard the vessel. These systems can be mounted up to 50m offset from the installation location of the structure. The inertial data sensed at these locations is processed to compute the absolute attitude of the structure. The system enables the offshore team to determine the verticality and heading of the structure automatically without having to pause hammering or physically mount any sensors to the structure.

VertiCAM Applications

VertiCAM is used to determine the verticality of tubular structures, with several applications in offshore renewables. These applications include:

- Offshore Wind Farm Installations:

- Structure Piles

- Wind Turbine Pile Foundations

- Jackets

How VertiCAM Works

For monitoring the pitch and roll of the pile during installation, this is how VertiCAM works:

- System Setup and Installation: Install two or three "stations" of the VertiCAM system on the vessel. Two of these systems are active for dual redundancy, and the third system may serve as a "hot" spare system for backup.

- Sensor Configuration: Each "station" will be equipped with the following sensors:

-

- LiDAR

- Camera/Lens

- Lights

- Inertial Measurement Unit (IMU)

- GNSS receiver and antenna

- Processor

- Pile Installation Process: VertiCAM monitors the pitch and roll of the pile as it is lowered into place and continuously tracks the pile's verticality. The LiDAR solution delivers the required accuracy/resolution without any specific targets being placed onto the pile. The camera solution requires targets to be installed and dimensionally controlled onto the structure.

- Real-Time Data Processing: The structure is detected in real-time by the LiDAR-camera system at two different angles. The inertial data is then processed to compute the high update rate absolute attitude of the structure, independent of the motion of the installation vessel.

VertiCAM Key Features

- VertiCAM is a dual redundant solution, combining a LiDAR system, HD Imaging Sensor, and IMU at two different viewing locations for a structure being installed.

- VertiCAM is a contactless, in-air solution that positions a structure with no sensors or physical bracketry mounted to the structure.

- The verticality data is provided to the user in real-time.

- The LiDAR system will perform down to the onset of “zero” or “very low visibility” as defined by ICAO Annex 3 Meteorological Service for International Air Navigation.

Data Acquisition and Requirements

This system is connected to an NVIDIA GPU processor running real-time verticality calculations, also providing a remote human-machine interface (HMI) processor connected to the core processor via a network (Ethernet) connection to allow remote data viewing and interface to the system.

Product Specs

- Exterior Sensor Housings - IP67/IP68 Housed

- Pitch and Roll Required (Accuracy) - Target 0.05°, Minimum 0.1°

- Pitch and Roll Required (Resolution) - Target 0.01°, Minimum 0.05°

- Heading Accuracy - <1° *If structure Features Are Present

- Pitch and Roll Range - +/- 20°

- Maximum Vessel Motion - +/- 10° Pitch/Roll, +/- 3m Heave, 5°/s Rate of Rotation

- Max Offset From Pile to Sensors - 20m Imagery, 50m LiDAR

- Pile Dimensional Control Information - Diameter +/-3mm, Ovality 5%

Contact Zupt today to learn more about VertiCAM and how it can enhance your offshore operations.

HaloCAM

The function of HaloCAM is to monitor the verticality, heading, and relative position of any subsea structure with a fiducial target; in our case, we chose the ‘April Tag’ family of targets that are adhered to the structure. The integration of a high-resolution machine vision camera with either a navigation-grade INS (delivers heading) or a MEMS IMU (just pitch and roll) forms a powerful contactless subsea imaging and positioning solution with real-time data transmission to the surface.

The information available through HaloCAM includes altitude/ stick-up height, roll, pitch, and the relative heading of the target in relation to the ROV. If the navigation grade IMU is selected, then no heading sensor is required on the ROV. If the MEMS IMU is selected, then the ROV’s heading sensor can be integrated. This ability to position a structure in real time with no sensors or contact with the structure can significantly enhance the efficiency of subsea monitoring, especially when assessing the verticality of subsea structures with tight tolerances.

HaloCAM Applications

HaloCAM is designed for efficient offshore energy installations and is a versatile solution suitable for various applications, including:

- Oil And Gas

- Well Spudding

- Conductor/Casing Installation

- Offshore Wind Farm Installations

- Monopile monitoring

- Subsea Template Installation

How HaloCAM Works

HaloCAM combines advanced computer vision and inertial navigation techniques. Here's how it works:

- Mounting & Installation: HaloCAM is securely mounted at the front of the ROV with an unobstructed view of subsea assets. The fiducial target is installed on the structure.

- Dimensional Control: While either onshore or offshore, dimensional control checks are performed between the target and the structure to ensure precise placement and alignment relative to the structure.

- ROV Deployment & Positioning: The ROV is deployed and strategically positioned to optimize visibility for HaloCAM while maintaining a safe distance of at least 2 meters off the structure.

- Data Acquisition: HaloCAM recognizes the target, sending offset position, pitch, roll, and relative heading data to the surface. Using our specific targets, we also provide quality control metrics for each of these parameters.

- Real-time Processing: The resulting data is transmitted to the surface user via a simple RS232 link with an update rate of 5 Hz.

HaloCAM Key Features

- Contactless Data Collection: Contactless data collection through HaloCAM significantly reduces the cost and HSE risk associated with placing expensive sensors onto piles, conductors, or structures offshore.

- Accuracy of +/- 0.2°: HaloCAM offers an accuracy of +/- 0.2° degrees in verticality - assuming clear visibility to the structure and the system is within a clear line of sight to the structure in question. The positioning accuracy and update rate of HaloCAM are not affected by shock or acoustic noise from hammering or jetting during installation.

- Simple Integration with the ROV: The mobilization is quick with a single connection to an ROV survey port.

- HaloCAM works with targets applied directly onto the rounded face of conductors/monopiles.

- Absolute Positioning: In cases where absolute positioning of the structure is required, HaloCAM can incorporate data from the ROV’s navigation solution, further enhancing its positioning utility.

Data Acquisition and Requirements

HaloCAM incorporates a non-ITAR controlled inertial measurement unit (IMU) and can be easily deployed on an ROV using a single connector (24Vdc, 75W), providing real-time data to the surface. With a Navigation grade IMU, HaloCAM can remain mounted on the ROV and function as a precise subsea INS when not actively used for structure positioning. If a project deliverable does not include a precise structure heading, HaloCAM can be made available with the MEMS IMU as a more affordable solution.

Contact Zupt today to learn more about HaloCAM and how it can enhance your subsea operations.

Floating Mast Installation Support

VertiCAM is a contactless camera-inertial solution that streamlines the installation process of Floating Wind Turbine Generator (WTG) foundations and turbine masts. This integrated solution determines the real-time position and verticality of structures with precision, meeting the high-accuracy installation tolerances required by floating WTG foundations and turbine masts.

When installing WTG masts from or onto floating structures, motion-compensated sensors are crucial for the WTG mast’s alignment and verticality. Zupt's VertiCAM emerges as a precise solution, ensuring the alignment and verticality of WTG masts to process positioning data independent of the motion of the installation vessel. As a contactless solution, VertiCAM offers flexibility and ease of use. Zupt’s solution does not require physical bracketry to be mounted to the mast or foundation and includes equipment that is easily mobilized and demobilized from the vessel in question.

Contact Zupt today to learn more about floating mask installation support and how it can enhance your offshore operations.

Transmission Line/Structure/As-Built Inspection

Zupt's subsea modeling system, known as '3D Recon', delivers accurate and detailed 3D models to create digital twins of newly installed or existing infrastructure, subsea transmission lines, pipeline free span, and much more. These models are geospatially correct and can offer submillimeter pixel resolution representations of subsea structures up to depths of 4,000 meters. The high-resolution models may be utilized for asset integrity, as-built models, metrology, and GVI to aid in making informed decisions on structural health.

3D Recon delivers a complete model of the structure, allowing subsea integrity engineers to have a big-picture view while also maintaining the details necessary to make decisions on the asset. Subsea engineers can then focus their attention on particular areas of interest, zooming in and navigating around the 3D model to make distance, angular, and volumetric measurements with known accuracy. This ability enables them to quickly gather detailed information about the structure's condition to assess structural integrity and facilitate proactive decision-making.

Contact Zupt today to learn more about subsea Transmission Line/Structure/As-Built Inspection applications and how they can enhance your subsea operations.

Subsea Monopile Installation Monitoring

HaloCAM is a uniquely developed contactless camera-inertial solution that integrates a high-resolution machine vision camera with a navigation-grade Inertial Navigation System (INS) to provide real-time data positioning for monopiles during installation. The real-time data transmitted to the surface includes crucial parameters such as altitude, inclination, roll, pitch, and relative heading of the target concerning the Remotely Operated Vehicle (ROV).

HaloCAM proves instrumental in the installation of monopiles subsea for offshore wind farms, where precise installation is crucial for the overall efficiency of renewable wind energy generation. These monopiles, ranging from 5 to 7 meters in diameter, are driven into the seabed and serve as the sturdy foundation for supporting wind turbines that will later be installed on top. The verticality of these monopiles significantly impacts the structural integrity and longevity of the wind turbines; because of this demand for precise verticality, there are highly accurate installation requirements from operators. HaloCAM serves as a tool for overcoming these challenges to achieve these accuracy demands.

HaloCAM is a standalone and contactless system mounted to an ROV. HaloCAM combines machine vision camera data with the ROV positioning solution to determine the absolute position of the structure to the same level of positional accuracy as the subsea vehicle (USBL or LBL) positioning.

With its contactless capabilities, HaloCAM can precisely measure the attitude and differential depth of a target positioned on any monopile. This marks an advancement in the Renewable Energy sector, as it eliminates the need for time-consuming/laborious and hazardous manual installation of bracketry typically required for subsea gyros or acoustic transponder buckets in traditional methods.

Benefits of Contactless Subsea Monopile Installation

- Contactless Data Collection: Streamlining installation procedures, our solution eliminates the necessity for physical brackets and sensors attached to monopiles.

- Real-Time Monitoring: Achieve accuracy and precision with complete visibility into the verticality of your monopiles throughout the installation process.

- Enhanced Safety: Prioritize the safety of offshore operations by eliminating the risks associated with physical sensor installations.

Contact Zupt today to learn more about subsea monopile installation applications and how they can enhance your subsea operations.