Get in touch with us for any questions or quotes on surveying services and products. We will respond back as soon as we can.

Remote Subsea Metrology

250+ Metrologies Successfully Completed

Our team has completed over 250 reliable and accurate metrologies for our clients. The small footprint of the system and ease of mobilization has been proven through multiple long-term contracts completed globally, including in West Africa, the Gulf of Mexico, Central America, and the North Sea. It is the proven efficiencies of our techniques that enable us to now offer lump sum and remote subsea surveys to our clients.

Remote Metrology Benefits

- Accommodates Drilling Schedule

- Fully Remote Solution

- Fixed Cost Metrology

- Eliminate Survey POB

- Real-time Quality Control

- 24/7 Onshore Support

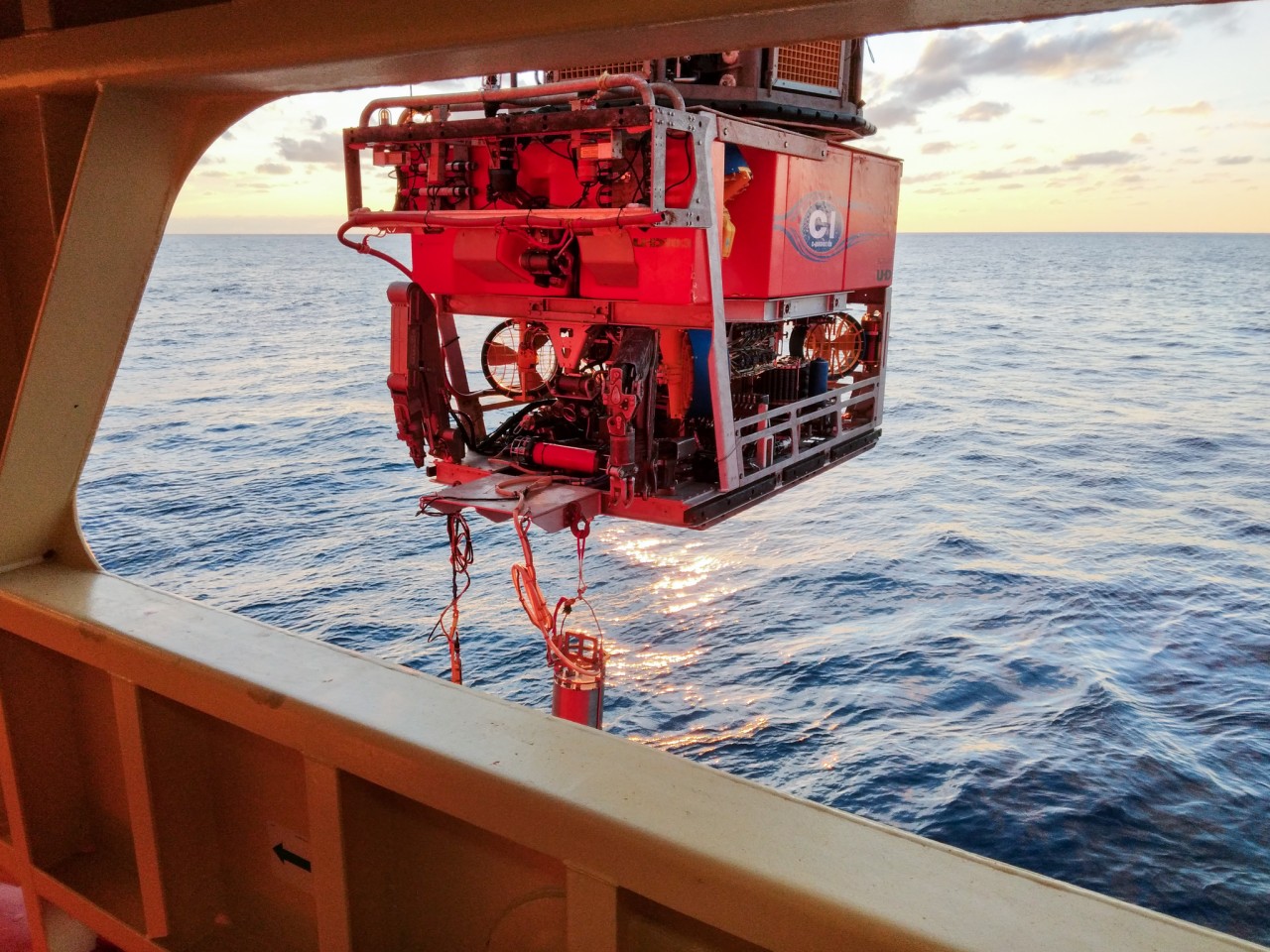

Equipment Spread

The equipment required for a remote metrology is the same, whether manned or remote. The only subsea positioning equipment needed is Zupt's C-PINS inertial navigation system, a single bottle carried by the ROV. The entire spread is contained in 6 transit cases including a complete set of spares, with a total kit small enough to fit in a traditional passenger van.

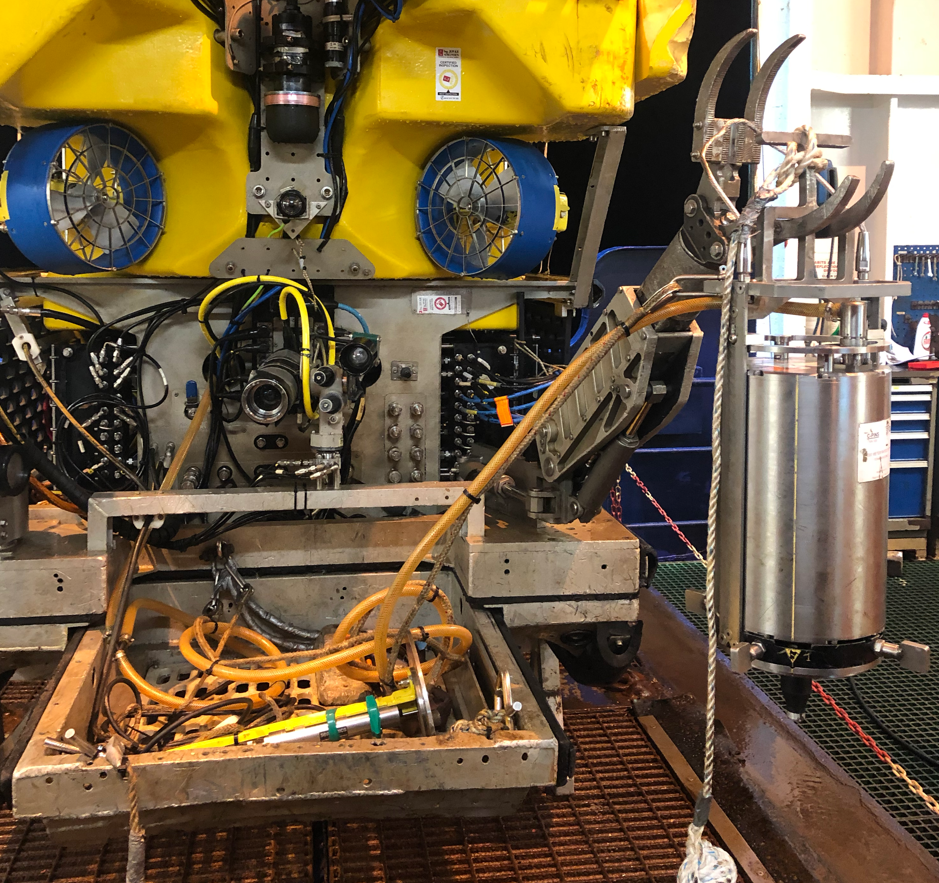

Equipment Interfacing

The simple interfacing is performed by the ROV crew onboard the vessel or rig through instruction provided by the onshore metrology team. Typically, on a large campaign, we provide ROV crews the option of a C-PINS interfacing course before the first remote metrology. But in reality, C-PINS require just a single serial channel (24V, RS232) to the surface from the ROV; no fiber splicing is needed. The equipment spread essentially a plug-and-play solution for the ROV to install. Then, pictures or videos of the mobilized ROV are sent back to Houston, and the onshore metrology team confirms the cabling is adequately secured and the C-PINS is stowed safely for deployment.

Data Collection

C-PINS are fully controlled by the onshore metrology team with two-way (Tx/Rx) serial communication with the C-PINS on the ROV from the laptop onshore (data rate is 38,400bps to the C-PINS on the ROV). The survey data is not transferred from offshore but collected in real-time from the C-PINS to the data acquisition laptop collecting the metrology data onshore. Meaning, we collect that data onshore and perform the same real-time quality control that we do on our manned metrology operations. We have the same control over C-PINS onshore that we do sitting in the ROV control van.

Communication With Clients

Client liaison is another area where we have found great benefit in being onshore. As with our manned metrology work – we have a client-reviewed and agreed-on task plan. The client can be in the control room with us, offshore on the vessel/rig, or in their office onshore. Just like calling up to a vessel supervisor from the ROV van – we can call the same supervisor from the control room to keep them abreast of where we are in our operations.

Quality Control

We know how good the data is as we are collecting it. We focus on this with our surveyors to make sure we move on to the next section of the task plan once we have the data needed to fulfill the specification. We do not collect excessive data – just in case. The raw data that a client would want to QC (the OpLog in our case) can be made immediately available across the table or via email to anyone that wants to QC the data. With an average file size of around 65kb, the data is easily transferable. Many of our clients have built their own macros for automatically importing and populating their QC spreadsheets.